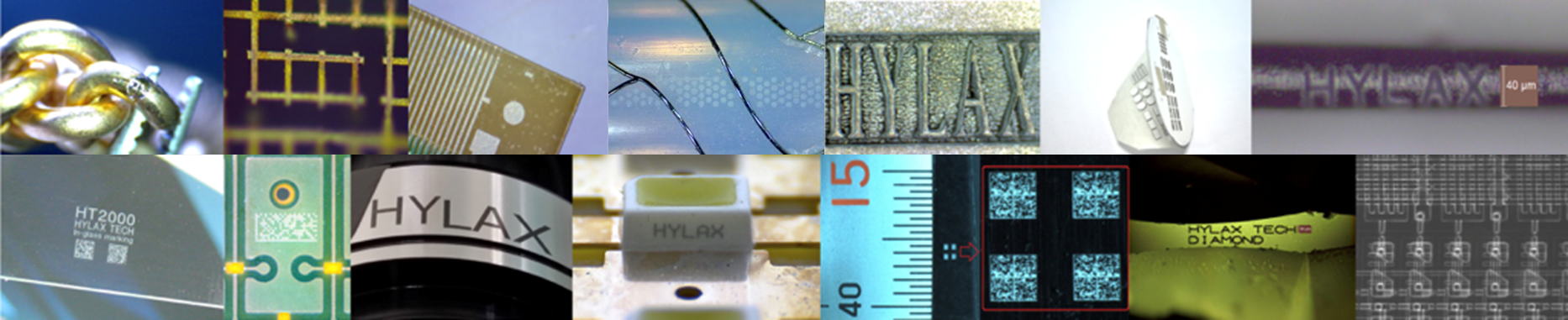

Laser micro machining of hard and brittle parts are becoming more mainstream with the advent of new laser sources capabilities and cost effectiveness. It is a flexible, clean and fast way to achieve results not possible before. With small laser beam spot size, high power and short pulse, material removal can be controlled to allow miniature forms to be machined with minimal heat affected zone. Hard materials like Inconel can be machined and also brittle materials can be structured with sharp and well defined shapes.

Please contact us today to discuss your requirement.

With the ultra short pulse technology that facilitate a non thermal laser processing which commonly know as ” cold laser ablation” resulting in an adiabatic process which heat is being removed through the ejection of ablated materials. With no recast, splatter of molten particles contaminants and micro cracks on the material after the laser process.

With the addition of Hylax’s proprietary Scanvison™ Technology, the system is brought to the next level of precision and accuracy. It is able to achieve process landing accuracy of +/-15um.

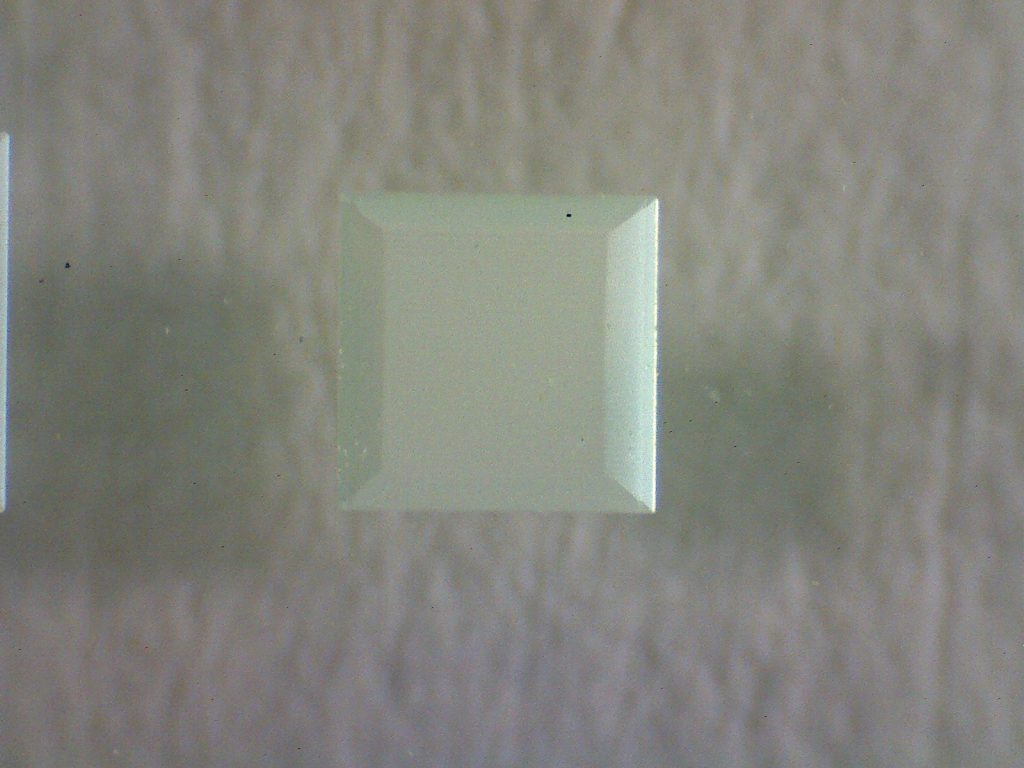

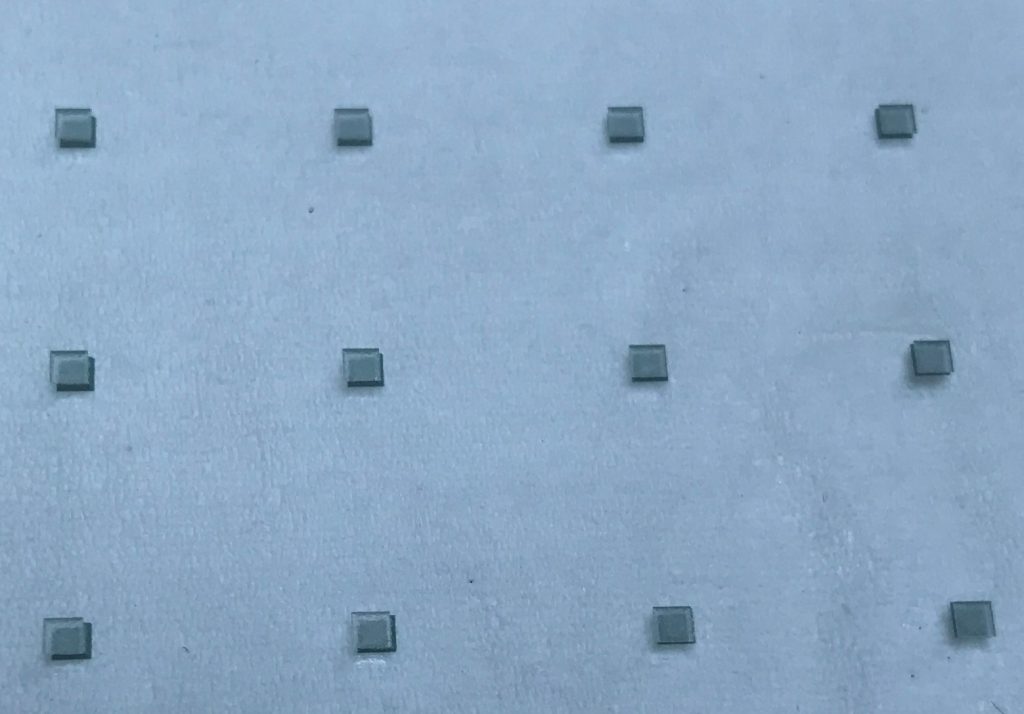

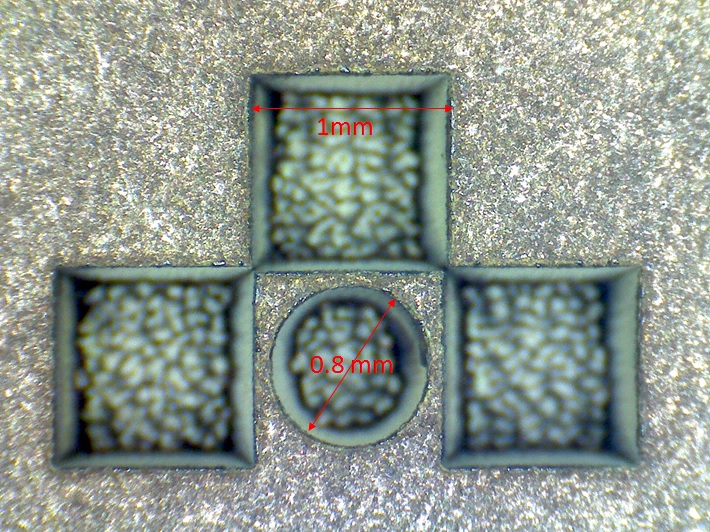

Material removal on glass substrate

Machining into glass can be done easily by the right type of laser. Micro structures, micro patterns and very fine features can be created by removing layers from the glass substrate. The feature below is 2.4 mm x 2.4 mm x 0.45 mm deep. The feature is sharp and clean with negligible heat affected zone.