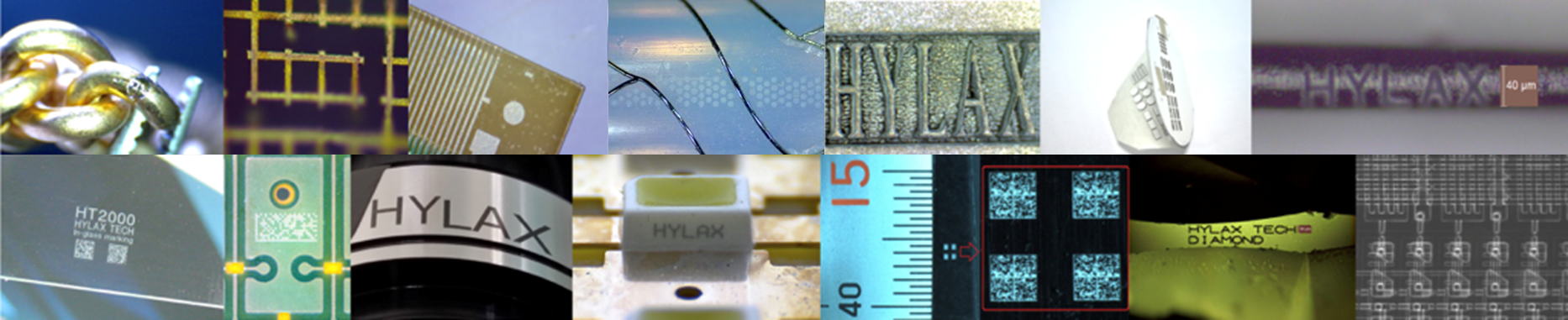

Copper laminate multi-layer materials singulation

Copper laminate wafers with multi-layers of different materials with varying hardness and density is difficult to singulate cleanly. With the drive towards smaller form factor the task becomes more complex. Using lasers becomes an attractive option. However previously charring and cycle time were issues in this laser cutting process. With the advent of new types of lasers and Hylax technological expertise we have solved the problem.

Bare wafer laser scribing

Laser can also be used to scribe silicon wafer. Scribing causes partial cut lines on the wafer. This lines introduces regions of weakness. This is usually followed by a mechanical breaking procedure to produce silicon rectangular tiles for subsequent operations.he mechanical break will follow allowing the scribing line offering the least path of resistance. The laser is a high throughput, cost effective and simple way to effect the scribing with accuracy and long term reliability.

See also:

http://www.hylax.com/wafer-laser-mark/

http://www.hylax.com/wafer-ring-n-substrate-handler/