Laser with the Gift of Sight…

In-line Vision Laser Technology

Cutting edge vision assisted precision

laser processing solution

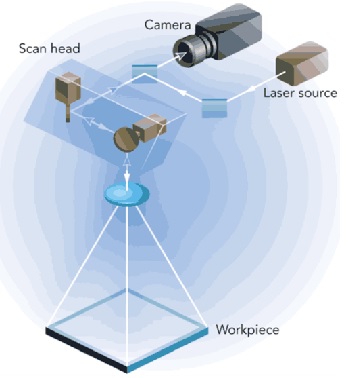

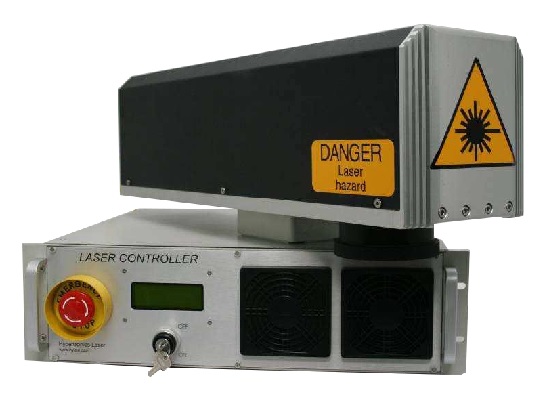

Hylax’s proprietary Scanvision™ Technology combines a vision camera system and a laser system together to offer high precision with high speed laser processes like marking, welding, cutting, drilling and surface processing etc.

By positioning the camera in-line with the laser path, visible light for the vision camera travels in the same path as the laser beam, through the galvanometers beam positioning system.

This makes it possible to achieve real-time vision compensation of work piece drift or fiducial find with accuracy up to 3 microns in milliseconds. All tolerances of conventional vision assisted laser system such as X-Y table, F-theta lens, galvanometers positioning errors, work piece and jig tolerance etc., are therefore eliminated.

Scanvision™ features & advantages

- In-line visible light and laser beam near perfect coincident to each other with near zero tolerance between laser beam and vision light path.

- High speed movement in milliseconds and high accuracy in microns with large area coverage by movement galvanometers to deliver and perform:

* Vision check

* Orientation check

* Fiducial find

* Pre/post mark inspection

* Laser processing

* 2D data matrix verification

* OCR read back

- Active X,Y and theta drift work piece misalignment compensation without moving the work piece.

- No need for expensive jig and fixture for work pieces to achieve accuracy.

- Real time point of mark inspection and viewing before and after laser process to achieve zero escape.

- No need to shuttle work piece between laser and camera positions (only galvanometers move) resulting in:

* Reducing processing time, delivers much higher throughput

* Small work envelope requirement with compact design

* Elimination of tolerance associated with mechanical movements

- Vision check and laser processing performed almost simultaneously.

- Proven software interface in Visual Basic, C#, “C++”, Ethernet and RS 232 to link to 3rd party software for complex solutions and customization.

- Powerful image processing software built around Cognex Vision Library.

- Scalable processing heads with simultaneous and concurrent laser process for big area coverage.

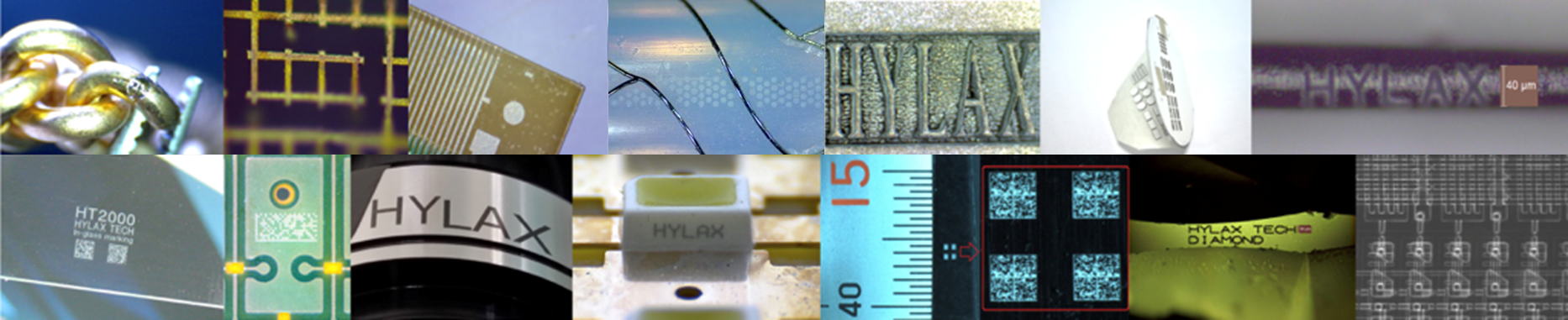

ScanVision™ application showcase

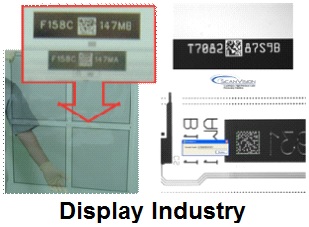

Display Industry

* Titler

FPDs are usually manufactured in big panels with a numbers of subpanels. Panel IDs in the form of text and 2D matrix or Veri-code are needed to be marked on pads as same as 0.8mm in height in each subpanel. The ScanVsion™ achieves an accuracy of +/- 15um at high speed marking process by using galvanometers movement for fiducial, mark and verification in each marking location.

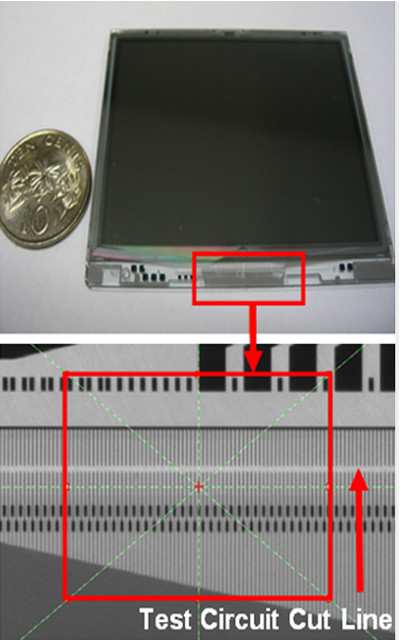

* Trimming

Test circuits are built into the LCD panels for the final test and after testing, the tracks of the test circuit have to be trimmed off. The accuracy requirement can be as high as +/- 10um.

ScanVision™ achieves high precision and speed by using the galvanometers movement to perform fiducial find, drift compensation, laser trim process and post trim check almost simultaneously whereby increasing the throughput by 3 folds over the conventional systems.

HDD Industry

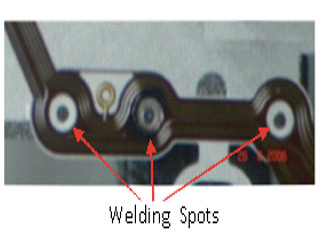

* Precision micro welding

HDD suspension consist of several layers of material that need to be welded together. Depending on the type of suspension, on average there are maybe 20 over spots and the parts are small requiring very small spot size weld.

* Laser surface polishing

Laser polishing are performed on very minute components of the HDD suspension. The Scanvision™ is able to capture the polish location quickly and perform the positioning compensation and laser polishing process at a very high speed. Upon completion of the laser polishing process post inspection is performed to ensure that the polishing is done properly and to detect any material defects achieving 1 ppm quality output with zero escape.

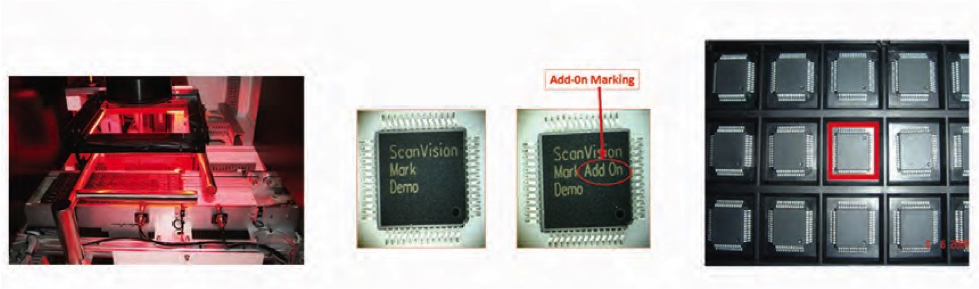

SEMICON Industry

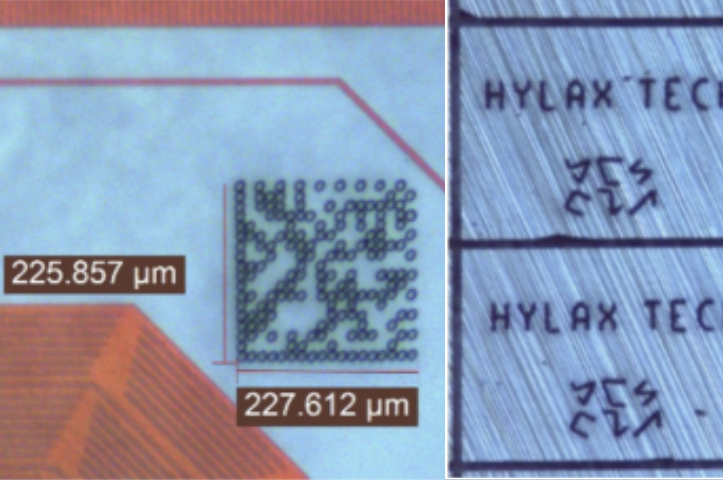

* Singulated CSP wafer level marking on tape

Scanvision™ with high speed galvanometers movement is able to achieve pre-alignment sequence, marking and post mark verification almost simultaneously achieving accuracy of +/-10 um and 400k UPH on 6 characters of 50um characters height

* IC package add on marking

Where there is need for add on marking to ICs Scansion allows the previous marking to be registered and new marking align properly so there is no shift or discernible difference between both. Marking of ICs in a tray is also accurate because of per package vision check and compensation.

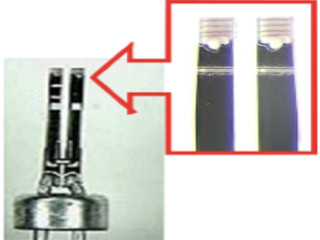

* Crystal trimming

Quartz crystal such as those used in the watches can be trimmed with laser to achieve a specific resonance range. The accuracy requirement can be as high as +/- 15um.

The ScanVision™ with the fast galvanometers movements is able to identify the trim location and to perform the trim almost simultaneously with accuracy and doubling the throughput over the conventional system. Applicable to resistor and RFID antennae micro trimming etc.

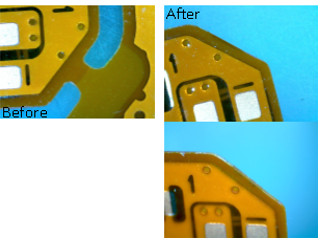

PCBA Industry

* Flex circuit depaneling

Scanvision™ with high speed galvanometers movement is able to achieve pre-alignment sequence and laser depaneling process without shuttling the work piece, achieving cutting accuracy of +/-18um.

LED Industry

* Ceramic marking

Scanvision™ with high speed galvanometers movement is able to achieve pre-alignment sequence, marking and post mark verification almost simultaneously achieving the accuracy of +/-15 um.