Glass marking with lasers is a proven method and used in many applications. It is mainly used for fine marking for identification, traceability and branding requirement. It can also be a counterfeiting deterrent measure. One way to mark on glass if a coating is first deposited on the glass surface. The laser marking is then done on the coating instead of on the glass itself. The coating may be formed during some other manufacturing process so an additional step is not required. This is done in LCD glass panel manufacturing. See http://www.hylax.com/glass-panel-laser-equipment/. However there are cases where there is no surface coating and direct marking on bare glass is necessary. We have 3 methods to mark on bare glass.

Scribing mark: Using a UV/green laser to perform surface scribing mark on the glass material. The mark contrast presentation is good but the down side is during the marking process glass debris will be generated and micro cracks may be introduced. If your glass product goes thru temperature cycling, the micro cracks may propagate. Even normal environment temperature changes can cause this microcracks to propagate slowly over time.

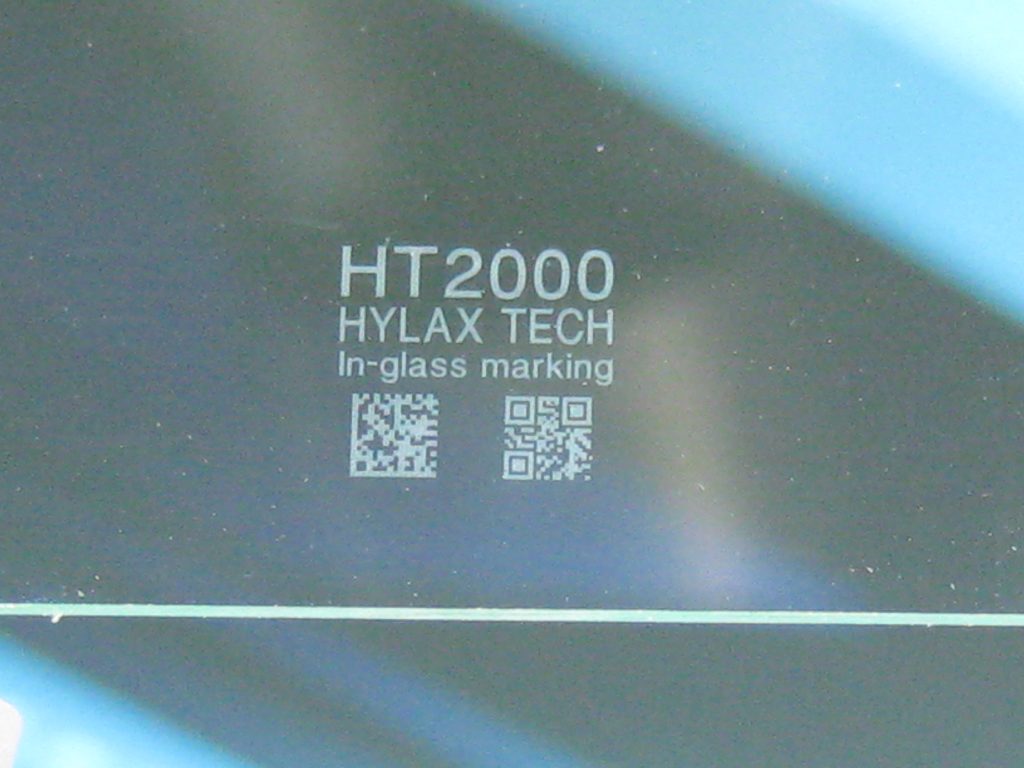

In-glass marking: Using a UV laser to perform in-glass marking. This approach will give good mark contrast and no debris will be generated. The down side of it is, the laser spot is focussed within the glass causing vaporisation and micro cracks in the glass to create the mark. When the product goes thru the temperature cycling the micro cracks may propagate. For marking in thin glass panels like flat panel display, control over the Z focus accuracy is critical. The bubble formed inside the glass is in 100s of microns which is nearly the thickness of the glass itself.

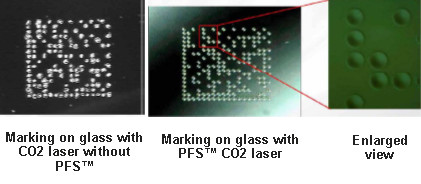

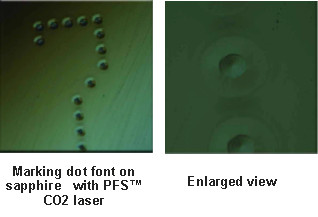

Surface soft mark: For this method we are using a CO2 laser to generate soft marking on the surface. A relatively good contrast mark presentation is created and minimal glass debris is generated. The Co2 laser will melt the glass during the process. It will withstand better temperature cycle since there is no micro cracks generated. This soft mark method is only made possible by our proprietary power feedback control module in the Co2 laser marker. Only dots can be produced by this method. Our marking software has dot fonts available for this type of mark and new font types can be created easily in Hypermark. 2D codes like data matrix marks can easily be read with this type of marking.

Below are some images of the different approaches:

Coupled with a ultra stable solid state DPSS laser, Hylax HT2000 series of UV laser marking systems are capable of producing debris free in-glass laser marking on ultra thin glass substrate of 0.3mm thickness.