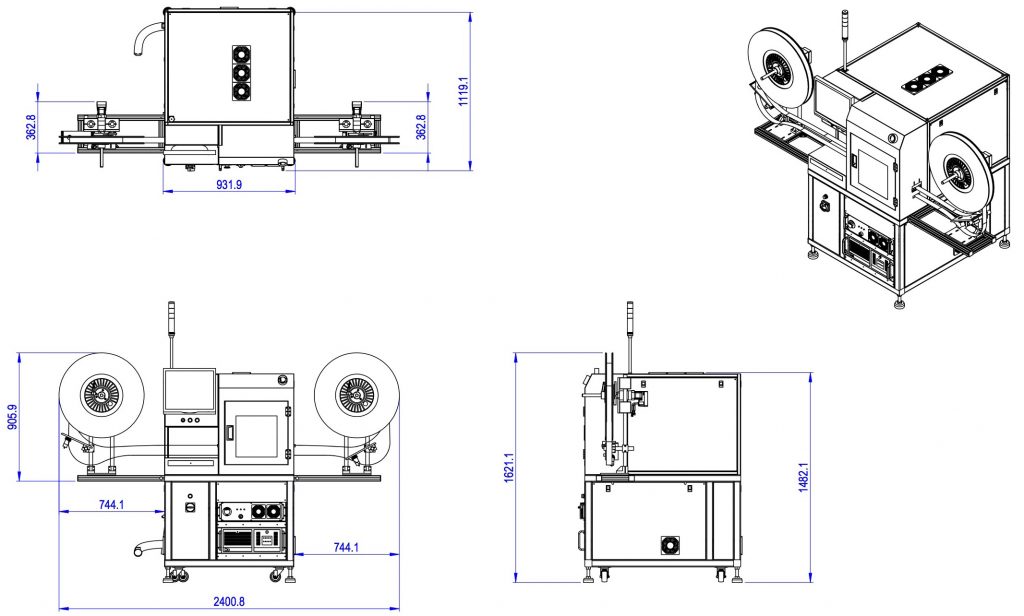

Hylax Technology has expertise in designing and building reel to reel auto handling systems for laser processing. The reels are mounted on spindles with gripper to hold and turn the reels. A reel is rotated by a motor controlled to unwind or wind according to the slack of the reel. Both input and output spindles are the same mechanism with different programming.

There is provision for interleave handling if required. One method is for the input stage to drop the interleave into a box and draw new interleave from a stack at output stage. Another method is to draw the unspooled interleave through the machine and combine it back with the reel at the output end.

All the modules are combined together into one compact machine. The laser processing scanvision module rest on an anti-vibration platform to ensure stable operation for both the vision camera capture and for the laser marking. The enclosure is designed to protect operator from laser radiation with safety front window for monitoring the process.

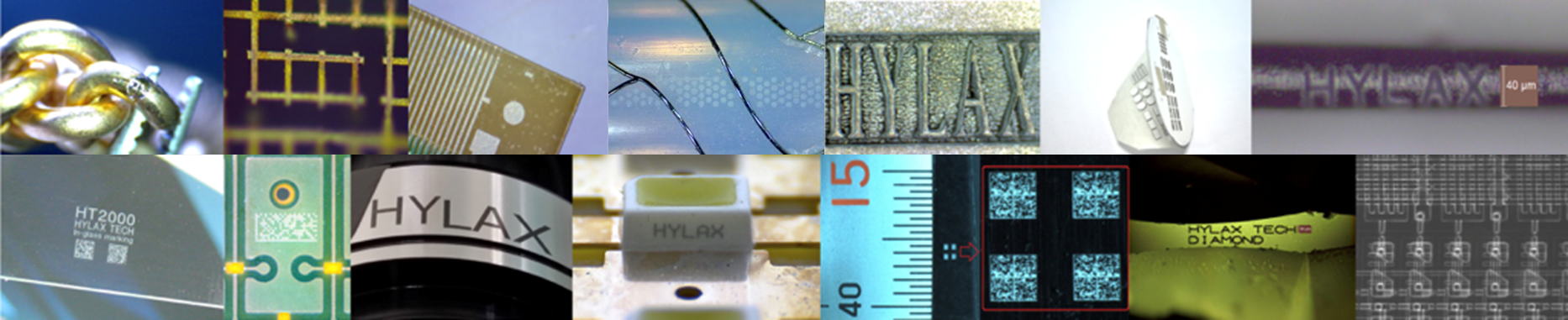

Marking on the side of products on a reel is a difficult process. This was made possible by a special large diameter sprocket wheel driven by a servo DDR. The sprocket wheel engages the holes in the reel and turns it at high speed with precision stopping. One row is marked at a time. For each row the product positions are not exact due to the non rigid nature of the reel. Upstream processes can cause the reel to be warped. The accurate placement of the mark is made possible by our patented scanvision system which registers the position of each product after every index.