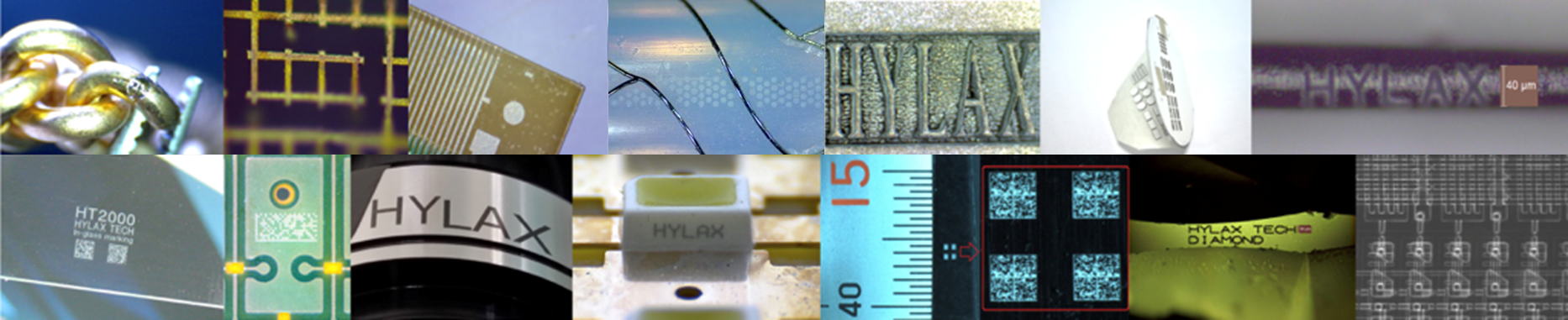

Laser smoothing of shiny metal surface

Lasers can be used to polish metal surfaces like steel to achieve better smoothness by a process such as metal surface melting through laser beam high intensity heating. Process parameter setting is critical to achieve good results in practise. As laser beam is very flexible, having many parameters to adjust such as energy, average power, pulse width, frequency, peak power, energy profiling with time a good result can be obtained for different kind of materials. Furthermore electronics control is precise and has long term repeatability makes this solution an attractive option for many industries. In hard disk industry this is one of the processes used in suspension manufacturing.

This is a fully automatic machine. Products are loaded into the machine in magazines. The lead frames are extracted using pick and place arms and placed into a rail where it is index to the laser zone for vision check for position drift compensation, the polishing process and finally a 100% post inspection of all parts. Fast 6000 uph is achievable.

Laser shiny marking by polishing of sandblasted metal surface

Another area of laser polishing is remelting metal surface to change its contrast thus creating a distinct smooth mark on the metal. This is a common method to mark logos on mobile phones casing. The result has an attractive hi tech look and feel. For this case the polishing mark is done on sandblasted aluminium. The surface remains smooth, there is no gross mechanical effect. The appearance change is caused by re-melting of the aluminium surface with a shiny result. Control is important to prevent too many remelted ripples.

See also http://www.hylax.com/laser-ablation/