There are many cases where there is a need to strip the coating off a wire. This may be insulation coating. One method to remove the insulation is by using a mechanical blade and scrapping the wire one portion at a time while rotating the wire. Or using a pair of pliers or scissors to scrap two surfaces simultaneously. However the method is slow and clumsy and also remove some of the wire material at the same time. Rotating the wire is not easy especially when the wire is small diameter. There is difficulty in keeping the wire at the same position after rotation.

Laser is another method to do wire stripping. It is fast and none intrusive unlike a mechanical operation. The wire is not affected structurally. And the coating can be removed without inadvertently removing some portion of the wire. This is by using a suitable laser wavelength which will only be absorbed by the coating and not the wire core. The coating will be vaporised by the heat from the laser. The result can be monitored closely by including a vision system for post inspection verification of the completeness of the removal.

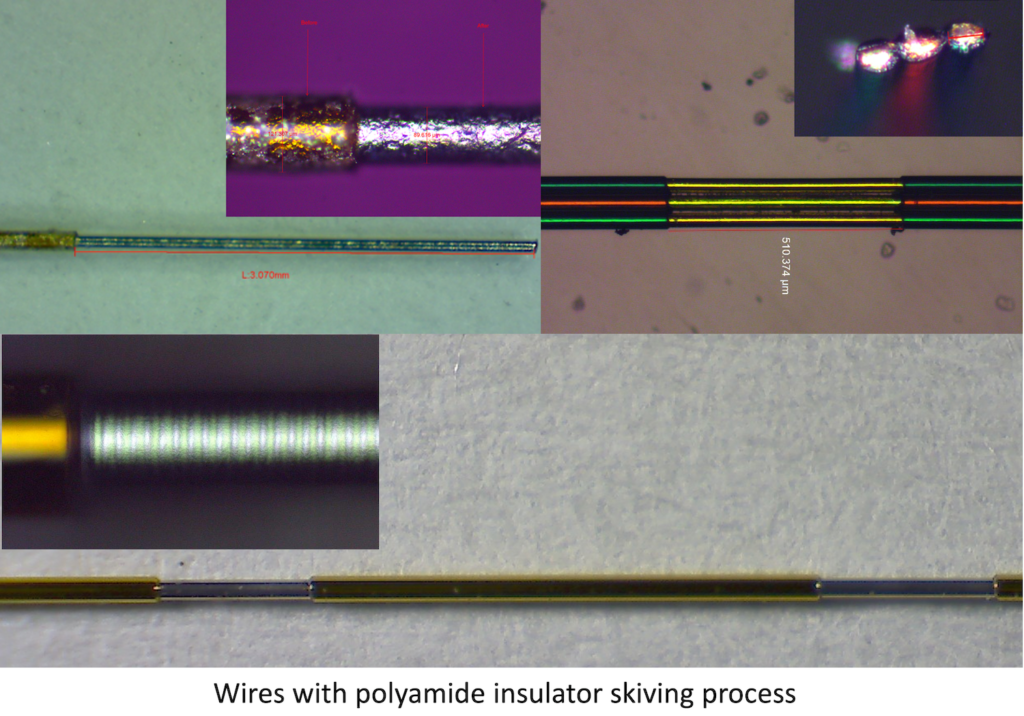

Using laser we can control the removal process finely to remove precise lengths of coating from the wire. Different lengths of removal can be programmed in. During indexing a vision system is used to ensure the process is accurate down to micrometer accuracy.

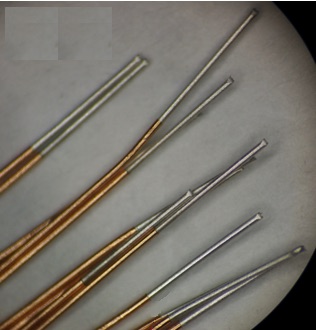

We have developed a simpler way to laser strip the coating of a wire without turning the wire. This is done by positioning mirrors strategically around the wire. The laser beam bounces off the mirrors in a circle to strip each portion of the coating. a small angle ensures there is adequate overlap to allow the laser beam to clean off the coating completely. The laser can be quickly steered by using a scanhead so this method eliminates many mechanical components and movements and increase the work speed significantly. By adding a camera vision we can inspect the coating removal at every angle to ensure that the job is done perfectly.[/vc_column_text][vc_column_text]The wire is stripped of it’s coating by a laser beam reflecting off mirrors placed around the wire for a complete and fast process. Below is a picture of wires after the process:

Fully automatic laser skiving machine for thin wires

Removal of selective layers and custom length patterns for thin wire is becoming an important need especially for biomedical applications for example used in inbody sensors. This process is also known as skiving. The clean removal, ability to control ablation depth and selective removal of different layers without affecting the inner core are important criteria in this application. This machine is able to do this using a combination of lasers that are able to affect different types of coating material on the wire. The machine works on a reel to reel concept. The wire is ablated by the laser in programmed lengths and patterns. It is then rotated to ablate the reverse sides. The result is verified by a vision system which measures the length and depth of the ablation to ensure good quality. The wire is then wound back onto an output spool. High yield and throughput is achieved with the machine.